Hot products

Product details description

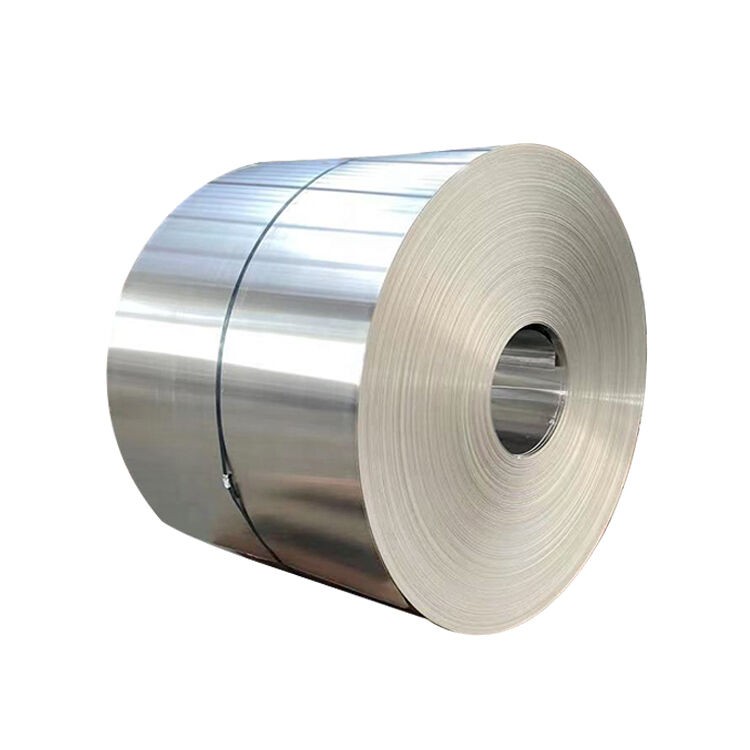

Introducing our Mill Finish Soft Aluminum Coil, a cutting-edge solution meticulously crafted for a myriad of applications. From its pristine mill finish to its soft, malleable nature, this aluminum coil, available in 1mm and 3mm thicknesses, stands as the epitome of precision and versatility. Let's explore the key features and diverse applications that make it the ideal choice for your cold aluminum roll needs.

Key Features:

Mill Finish Brilliance: Our aluminum coil boasts a flawless mill finish, delivering a sleek and polished surface. This not only enhances its aesthetic appeal but also ensures a smooth, consistent appearance, making it suitable for a wide range of applications where visual appeal is essential.

Soft and Malleable: The soft nature of this aluminum coil, coupled with its malleability, makes it incredibly easy to work with. Whether you're bending, shaping, or forming intricate designs, this coil provides the flexibility required for diverse cold aluminum roll applications.

Precision Cold Rolling: Crafted with precision through cold rolling processes, this aluminum coil guarantees uniform thickness and a consistent surface texture. The cold rolling technique enhances the coil's structural integrity, making it an ideal choice for applications that demand precision and reliability.

1mm and 3mm Thickness Options: To cater to varying project requirements, our aluminum coil is available in two thickness options – 1mm and 3mm. This versatility ensures that you have the flexibility to choose the appropriate thickness for your specific application, whether it's for intricate designs or robust structural components.

Corrosion Resistance: The inherent corrosion resistance of aluminum makes this coil a durable choice for both indoor and outdoor applications. Whether exposed to the elements or used in controlled environments, the coil maintains its integrity, ensuring a long-lasting and reliable performance.

Applications:

Architectural Cladding: The mill finish and malleable nature of our aluminum coil make it an excellent choice for architectural cladding applications. Whether for modern facades or traditional designs, this coil lends itself to the creation of visually appealing and durable cladding solutions.

Interior Design Elements: Utilize the soft aluminum coil for crafting interior design elements such as decorative panels, trim, and accents. Its malleability allows for the creation of intricate patterns and shapes, adding a touch of elegance to interior spaces.

Cold Rolling for Automotive Components: The precision cold rolling of this aluminum coil makes it suitable for manufacturing various automotive components. From trim details to specialized parts, the coil's consistency and malleability contribute to the production of high-quality automotive elements.

General Cold Aluminum Roll Applications: Whether you're involved in DIY projects, custom fabrication, or other creative endeavors, our aluminum coil is a versatile solution for various cold rolling applications. Its softness and mill finish open up opportunities for creating unique and customized designs.

In summary, our Mill Finish Soft Aluminum Coil in 1mm and 3mm thicknesses is a game-changer in the realm of cold aluminum roll applications. Elevate your projects with a coil that seamlessly combines precision, versatility, and aesthetic appeal. Choose excellence, choose flexibility – choose our aluminum coil for a cold rolling experience that exceeds expectations.

Aluminum rolling is widely used in electronics, packaging, construction, machinery and other aspects, Chinese aluminum rolling production enterprises are more, the production technology has caught up with developed countries, according to the different metal elements aluminum rolling contains, aluminum rolling can be divided into 9 big categories, that is, can be divided into 9 series.

1000 series

On behalf of 1000 series aluminum plate is also known as pure aluminum plate, in all series 1000 series belongs to a series containing the most aluminum. The purity can reach more than 99.00%. Because it does not contain other technical elements, the production process is relatively simple and the price is relatively cheap. It is the most commonly used series in the conventional industry at present. Most of the 1050 and 1060 series are in circulation in the market. The minimum aluminum content of 1000 series aluminum plate is determined according to the last two Arabic digits of this series, such as the last two Arabic digits of 1050 series is 50. According to the international brand naming principle, the qualified product must contain more than 99.5% aluminum. China's aluminum alloy technical standard (gB/T3880-2006) also clearly stipulates that the aluminum content of 1050 is up to 99.5%. In the same way, the aluminum content of 1060 series aluminum plate must reach more than 99.6%.

2000 series

2A16 (LY16) 2A06 (LY6) 2000 series aluminum plate is characterized by high hardness, among which the content of copper is the highest, about 3-5%. 2000 series aluminum plate belongs to aviation aluminum material, is not often used in conventional industry. Our manufacturers of 2000 series aluminum plate are less. The quality cannot be compared with abroad. The imported aluminum sheet is mainly supplied by Korean and German manufacturers. With the development of Chinese aerospace industry, the production technology of aluminum plate in 2000 series will further improve.

3000 series

Indicates 3003 3003 3A21. It can also be called rust-proof aluminum plate. Our production process of 3000 series aluminum plate is excellent. 3000 series aluminum plate is made of manganese element as the main component. The content is between 1.0 and 1.5. It is a series with good anti-rust function. Commonly used in air conditioning, refrigerator, car under humid environment, price is higher than 1000 series, is a more commonly used alloy series.

4000 series

The aluminum plate representing 4A01 4000 series belongs to the series with higher silicon content.The silicon content is usually between 4.5-6.0%. Construction materials, mechanical parts, forging materials, welding materials; Low melting point, good corrosion resistance Product Description: With heat and wear resistance

5000 series

Stands for 5052.5005.5083.5A05 series. 5000 series aluminum plate belongs to the common alloy aluminum plate series, the main element is magnesium, the magnesium content is between 3-5%. Also known as aluminum magnesium alloy. The main characteristics are low density, high tensile strength and high elongation. The weight of aluminum magnesium alloy under the same area is lower than that of other series. Often used in aviation, such as aircraft fuel tanks. It is also widely used in conventional industry. The processing technology is continuous casting and rolling, which belongs to the hot rolled aluminum plate series, so it can do oxidation deep processing. In our 5000 series aluminum plate belongs to one of the more mature aluminum plate series.

6000 Series

Represents 6061 mainly contains magnesium and silicon two elements, so concentrated the advantages of 4000 series and 5000 series 6061 is a cold treatment aluminum forging products, suitable for corrosion resistance, oxidation requirements of high applications. Good usability, excellent interface characteristics, easy coating, good processing. Can be used in low pressure weapons and aircraft joints.

General characteristics of 6061: excellent interface characteristics, easy coating, high strength, good usability, strong corrosion resistance.

Typical uses of 6061 aluminum: aircraft parts, camera parts, couplers, Marine fittings and hardware, electronic fittings and joints, decorative or various hardware, hinge heads, magnetic heads, brake pistons, hydraulic pistons, electrical fittings, valves and valve parts.

7000 Series

Represents 7075 mainly contains zinc. Also belongs to aviation series, is aluminum magnesium zinc copper alloy, heat treatment alloy, belongs to super hard aluminum alloy, has good wear resistance.7075 aluminum plate is stress-removed, will not be deformed and warped after processing. All the ultra-large and ultra-thick 7075 aluminum plates are detected by ultrasonic wave to ensure that there is no sand hole and impurities. The high thermal conductivity of 7075 aluminum plates can shorten the molding time and improve the working efficiency. 7075 is a high hardness, high strength aluminum alloy, often used in the manufacture of aircraft structure and futures. It requires high strength, corrosion resistance of high stress structural parts, mold manufacturing. Rely on import basically, our production craft still need to be improved. (The company once had a foreign company proposed that the domestic 7075 aluminum plate annealing is not uniform, the surface and internal hardness of aluminum plate is inconsistent problem)

8000 series

The more commonly used 8011 belongs to other series. In my memory, aluminum plate is mainly used to make bottle caps. It is also used in radiator, most of which are aluminum foil. Not very often.

9000 Series

Belongs to the standby series, the technology is so developed, in order to cope with the appearance of aluminum plate containing other alloying elements, the International aluminum Plate Federation specially indicated that the 9000 series is the standby series, waiting for a new variety to appear to fill the gap of the 9000 series.

Q1: Are you a manufacturer?