Hot products

Product details description

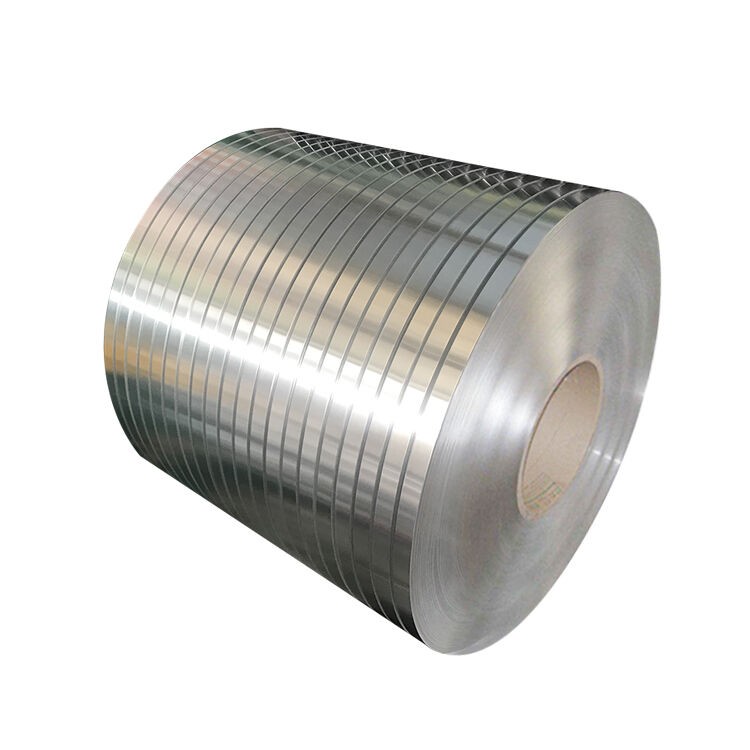

Introducing our Aluminium Alloy Mill Finish Aluminum Coil, a superior choice for marine applications that demand the highest standards of durability, corrosion resistance, and performance. Engineered with precision and crafted from premium alloys including 1100, 3003, 3105, and 5052, these coils stand as a testament to excellence in the maritime industry. Let's delve into the key features and applications that make them the preferred choice for marine construction.

Key Features:

Marine-Grade Alloys: The use of 1100, 3003, 3105, and 5052 alloys ensures that our mill finish aluminum coil is tailored to withstand the harsh marine environment. These alloys are renowned for their exceptional corrosion resistance, making them ideal for marine applications where exposure to saltwater and atmospheric conditions is inevitable.

Mill Finish Excellence: The mill finish surface offers a pristine appearance, characterized by a smooth and reflective surface. This not only enhances the aesthetic appeal of the aluminum but also contributes to its resistance against corrosion, providing a lasting and polished look for marine structures.

High Corrosion Resistance: Designed to resist the corrosive effects of saltwater and atmospheric conditions, these aluminum coils provide long-lasting protection against rust and deterioration. This makes them a reliable choice for marine structures, vessels, and components that require resilience in challenging maritime environments.

Lightweight and Durable: Aluminum's natural lightweight properties make it an ideal material for marine applications. The 1100, 3003, 3105, and 5052 alloys maintain this advantageous characteristic while also ensuring high durability, contributing to the overall efficiency and longevity of marine constructions.

Versatility in Applications: Our mill finish aluminum coil finds versatile applications in the marine industry. From hull construction to marine components, such as railing and trim, these coils offer adaptability and reliability, meeting the diverse needs of marine architects and engineers.

Applications:

Hull Construction: The superior corrosion resistance and durability of our mill finish aluminum coil make it an excellent choice for hull construction. Its lightweight nature also contributes to improved fuel efficiency and overall performance of marine vessels.

Marine Components: Whether for railings, trim, or other structural components, our aluminum coil is a versatile solution for various marine applications. Its resistance to corrosion ensures that these components maintain their integrity even in the harsh marine environment.

Boat Interiors: The lightweight and aesthetically pleasing mill finish surface make our aluminum coil an ideal material for boat interiors. From cabinetry to decorative elements, these coils contribute to a modern and functional interior design.

Marine Infrastructure: Our aluminum coil is well-suited for marine infrastructure projects, including docks, piers, and other structures. Its corrosion-resistant properties and durability make it a reliable choice for constructions exposed to the challenging marine environment.

In conclusion, our Aluminium Alloy Mill Finish Aluminum Coil sets a new standard for excellence in marine applications. Elevate your maritime projects with a material that combines durability, corrosion resistance, and a polished finish. Choose quality, choose resilience – choose our mill finish aluminum coil for marine constructions that sail above the rest.

| Mill finish aluminum coil/sheet | |

| International standard | ASTM specification -- American Society for Testing Materials specification. |

| Common aluminum alloy | 1 series, 2 series, 3 series, 5 series, 6 series, 7 series, 8 series |

| Thickness | 0.15-200mm |

| Width | 900-2000mm |

| Length | 2000-6000mm |

| Coil ID | 508/610mm |

| Temper | H, O, T |

| Standard Seaworthy Export Packing | plastic film, kraft paper, wooden pallet |

| Aluminum Application | ||

| Aluminum circle for Aluminum pot | 1050,1060,1100,3003,5005,5052 ,0.2mm-5mm | Aluminum pot has the advantages of beautiful, easy to remove dirt, lightness, durability, fast heating, even heat conduction and no rust. Cooking with aluminum helps protect vitamin C in vegetables, As a metal, aluminum is relatively light-weight, its light-weight make it easier for a manufacturer to form the cookware. Cookware made of aluminum is non-toxic. Aluminum cookware is easy to clean and can be recycled. |

| Aluminum Coil for Cans | 3004,3104,3015,5182,0.2mm-1mm | Aluminum alloy for Can Body, Can Lids and Ring Pull of Cans An aluminum can, is a single-use container for packaging made primarily of aluminum. It is commonly used for beverages such as coke, but also for products such as oil, chemicals, and other liquids. 3004 and 3104 grade aluminum alloy coil are the two main alloys used in can body. For beverage aluminum lids with the largest demand, including beer and carbonated beverages such as carbonated acid and alkali, 5182 h19 aluminum alloy was the most used, with common specifications of 0.249*827.89mm, 0.27*946.5mm, 0.22*911mm,etc. 5182 aluminum cans alloy is also the most representative material for ring pull manufacturing. |

| Aluminum alloy for Tank truck And Car Parts | 5454, 5182,1-20mm | Aluminum alloy for Tank truck And Car Parts A tank truck, gas truck, fuel truck, or tanker truck is a motor vehicle designed to carry liquids or gases on roads. The largest such vehicles are similar to railroad tank cars which are also designed to carry liquid loads. Therefore, it is necessary to use lightweight materials (Aluminum) to make the tank body to reduce the weight of the tank truck. The most common aluminum tank material is the 5 series and 6 series aluminum plate. The thickness of the aluminum plate for the tank body is generally 5mm. Also more and more automobile companies use aluminum alloy to make automobile body and auto parts, 5 series aluminum is the most popular for car using. |